Adhesive bonding techniques are essential in modern automotive manufacturing for advanced driver assistance systems (ADAS), offering advantages over traditional methods in compact designs. Specialized adhesives ensure strong bonds, maintain component integrity, and enable efficient assembly, precise placement, and secure attachment. This integration is critical for ADAS reliability in harsh environments and facilitates quick repairs, enhancing safety and structural integrity during collisions or maintenance.

Adhesive bonding techniques play a pivotal role in the advancement of Advanced Driver Assistance Systems (ADAS). As automotive electronics become more complex, precise adhesion methods ensure the seamless integration of sensors, cameras, and other components crucial for safety features like collision avoidance and autonomous driving. Understanding the interplay between advanced materials and adhesive bonding is essential to enhancing system reliability and performance in today’s increasingly sophisticated vehicles.

- Understanding Adhesive Bonding in Automotive Electronics

- Advanced Materials and Their Role in Driver Assistance Systems

- Enhancing Safety and Reliability through Precise Adhesion Techniques

Understanding Adhesive Bonding in Automotive Electronics

Adhesive bonding is a critical process in the automotive industry, especially for advanced driver assistance systems (ADAS). It involves using specialized adhesives to join various components within these complex electronic systems. This technique offers several advantages over traditional welding or fastening methods, particularly in compact and intricate designs. By carefully selecting the right adhesive, manufacturers can ensure robust bonding strength while minimizing part-to-part gaps, which is crucial for maintaining the integrity of sensors, cameras, and other critical hardware.

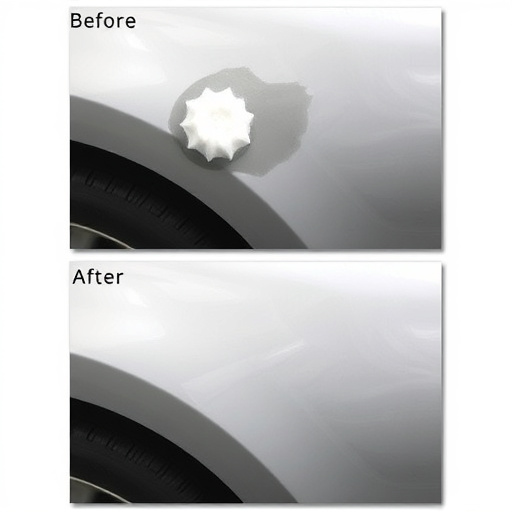

In ADAS, where space is often limited, precise placement and secure attachment are essential. Adhesive bonding techniques allow for the efficient assembly of sensitive electronics, ensuring reliable performance in harsh automotive environments. Moreover, this method facilitates rapid repair and replacement during collision damage repair or auto maintenance, contributing to cost-effectiveness and reduced downtime for car body repair.

Advanced Materials and Their Role in Driver Assistance Systems

Advanced Driver Assistance Systems (ADAS) are transforming the automotive landscape, enhancing safety and improving driving experiences. At the heart of this revolution lie advanced materials that play a pivotal role in enabling these systems to function optimally. These materials not only contribute to the lightweight design, but also offer superior mechanical and electrical properties crucial for ADAS components.

Adhesive bonding techniques are increasingly being employed in vehicle manufacturing to integrate these advanced materials into various subsystems. For instance, lightweight composites, including carbon fiber-reinforced polymers (CFRP), are used in structural applications, reducing weight and enhancing fuel efficiency. Meanwhile, specialized adhesives ensure robust bonding between these materials and metal components, ensuring the integrity of structures during extreme conditions like collision damage repair or automotive restoration. This seamless integration is vital for maintaining the performance and reliability of ADAS sensors, cameras, and other critical systems in a dynamic driving environment.

Enhancing Safety and Reliability through Precise Adhesion Techniques

In the realm of advanced driver assistance systems (ADAS), ensuring safety and reliability is paramount. Adhesive bonding techniques play a crucial role in this regard, offering precise connections that enhance structural integrity within vehicle components. By employing specialized adhesives, manufacturers can achieve robust bonds between diverse materials, such as metal, plastic, and composite structures, which are integral to ADAS components like sensors, cameras, and control units.

These precise adhesion techniques contribute significantly to reducing potential failure points in the event of impact or collision. In a collision repair center or car damage repair scenario, the ability to quickly and reliably replace or reinforce damaged parts using adhesive bonding streamlines the frame straightening process. This not only ensures the vehicle’s structural integrity but also facilitates faster turnaround times, making it a vital consideration for modern automotive manufacturing and repair practices.

Adhesive bonding techniques play a pivotal role in advancing driver assistance systems, ensuring safety and reliability. By leveraging advanced materials and precise adhesion methods, modern automotive electronics achieve superior performance and durability. As vehicle technology continues to evolve, a deeper understanding of these bonding techniques will be essential for the development of more sophisticated and efficient Driver Assistance Systems (DAS).