Adhesive bonding techniques provide a modern, versatile alternative to welding, creating strong, invisible bonds for delicate materials and intricate assemblies in industries like classic car restoration, paintless dent repair, precision engineering, electronics assembly, woodworking, vehicle bodywork, and Mercedes Benz collision repair. Choosing the right adhesive based on material types, desired bond strength, environmental conditions, and application-specific needs is crucial. Proper surface preparation ensures strong bonds, with polyurethanes and epoxies commonly used in auto repair due to their flexibility and resistance.

“Discover when adhesive bonding techniques surpass traditional welding. This comprehensive guide explores the benefits and diverse applications of adhesive bonding, from improved material strength to enhanced design flexibility. Learn scenarios where adhesives excel over welding, such as in complex geometries or delicate materials. Understand crucial factors like material compatibility, curing conditions, and bond strength to select the ideal adhesive for your project. Optimize joining processes and unlock innovative possibilities with adhesive bonding techniques.”

- Understanding Adhesive Bonding: Benefits and Applications

- When Traditional Welding Falls Short: Use Cases for Adhesives

- Choosing the Right Adhesive: Factors and Material Considerations

Understanding Adhesive Bonding: Benefits and Applications

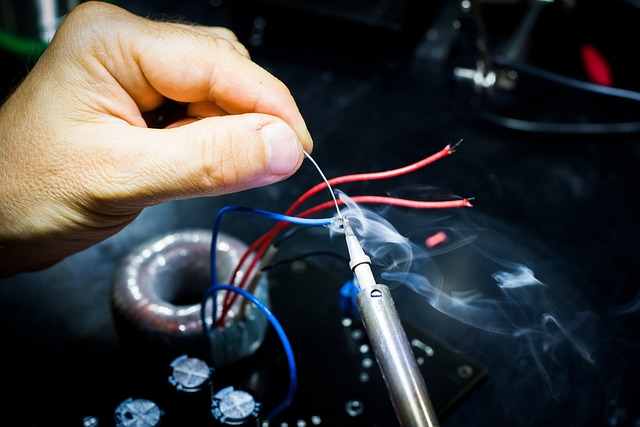

Adhesive bonding techniques are a versatile and powerful alternative to traditional welding methods. This modern approach involves using specialized adhesives to join materials together, creating strong and durable bonds. Understanding the potential of adhesive bonding is key to recognizing when it surpasses conventional welding in specific applications. Its benefits are numerous; for instance, it allows for the assembly of complex parts without the need for heat or extensive machinery, making it ideal for delicate materials that might be damaged by traditional welding methods.

One notable area where adhesive bonding shines is in classic car restoration and paintless dent repair services. In these scenarios, precision and aesthetics are paramount. Adhesive bonding techniques enable restorers to create seamless repairs, restoring vehicles to their former glory without unsightly weld marks. This meticulous process has revolutionized vehicle repair, especially in cases where traditional welding could compromise the integrity of the original body panels or leave visible scars.

When Traditional Welding Falls Short: Use Cases for Adhesives

In many industries, traditional welding has long been the go-to method for joining materials. However, there are several scenarios where adhesive bonding techniques offer superior advantages. For instance, in the realm of luxury vehicle repair, such as Mercedes Benz collision repair, precision and minimal material alteration are paramount. Adhesives can provide a strong, invisible bond that preserves the original integrity of the vehicle’s bodywork, making them ideal for complex paneling and trim pieces.

Moreover, adhesive bonding techniques prove invaluable when dealing with delicate or intricate components in various industries. Unlike welding, which can be destructive and leave visible scars, adhesives allow for precise application, ensuring minimal disruption to the overall design. This makes them particularly suitable for applications like precision engineering, electronics assembly, and even woodworking, where aesthetics and structural integrity are paramount—a benefit that extends to sectors such as vehicle bodywork and luxury vehicle repair.

Choosing the Right Adhesive: Factors and Material Considerations

Choosing the right adhesive is paramount when considering adhesive bonding techniques over traditional welding for applications like collision repair and car body repair. Several factors come into play, including the materials to be joined, the desired bond strength, environmental conditions, and specific application requirements. For instance, in auto repair near me, polyurethanes and epoxies are popular choices due to their flexibility and resistance to chemicals and extreme temperatures.

Material considerations are also crucial. Some adhesives work best with certain substrates like metal, plastic, or composite materials. The surface preparation is another key aspect; proper cleaning, degreasing, and roughening of surfaces ensures a strong bond. Understanding the compatibility between the adhesive and the materials being bonded enhances the effectiveness of the adhesive bonding techniques in various auto repair scenarios.

Adhesive bonding offers a versatile alternative to traditional welding, proving particularly effective in situations where material compatibility, complex geometries, or rapid assembly are key requirements. By understanding the benefits and selecting the right adhesive for specific applications, engineers and manufacturers can unlock a powerful method for joining materials, ensuring stronger bonds and enhanced product performance. Adhesive bonding techniques continue to evolve, revolutionizing various industries and solidifying their place as a game-changer in modern manufacturing processes.